Arrow Shell - A fin-stabilized HE projectile. In German, "Pfeilgeschoss."

Bag Ammunition - Ammunition in which fabric bags are used to hold the propellant and the projectile is handled separately. Propellant bags were primarily manufactured from a raw silk also known as "cartridge cloth" or else from a special coarse wool twilled on both sides known as "shalloon." Unlike cotton, these materials burn without leaving any smoldering residue in the barrel which would present a safety hazard when loading the subsequent round. Shalloon was used by most nations as it was relatively inexpensive but silk was preferred in the USN as it reduced barrel wear. Bags made from Rayon rather than silk were used in the USN for some guns after a serious propellant fire aboard USS South Dakota BB-57 in 1945 was traced to a spark generated when a silk bag was removed from its metallic container.

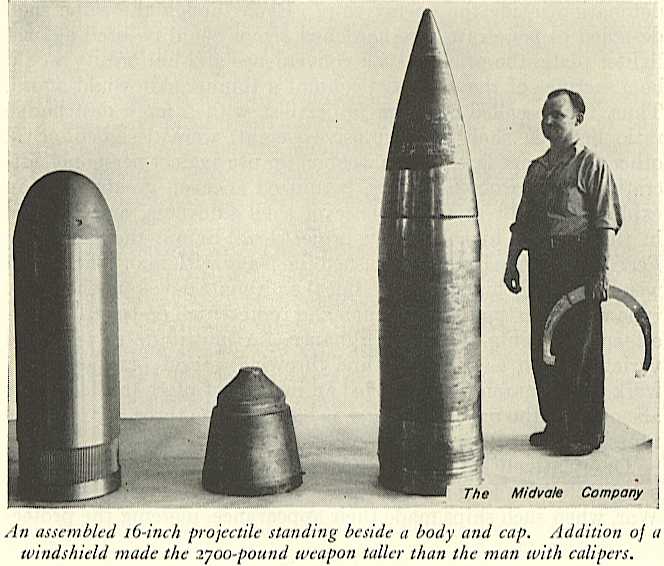

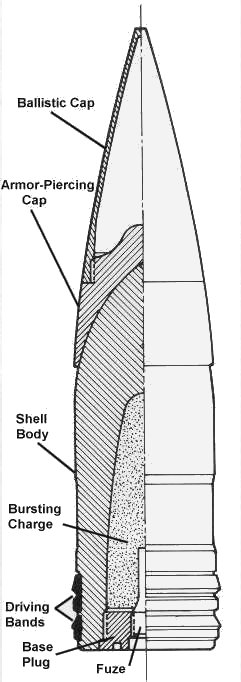

Ballistic Cap - Often called a "windshield," this is a covering on the nose of a projectile which is intended to provide a more streamlined shape for better aerodynamic - ballistic - characteristics. Not to be confused with a "Cap" or "AP Cap." See below.

Ballistic Coefficient - Measure of the ability of a projectile to overcome air resistance. Ballistic Coefficient (BC) = SD / F, where SD is the sectional density of the projectile and F is a form factor for the shape of the projectile. Sectional density is calculated from the mass (M) of the projectile divided by the square of its diameter. The value of F decreases with as the pointedness of the projectile increases. A projectile shaped like a sphere would have the highest F value while one in the shape of a long needle would have the lowest F value. The Ballistic Coefficient as normally defined contains a term for the so-called 'form factor' and is usually represented by the letter i. Under normal conditions, the value of i - and hence the Ballistic Coefficient - will vary (at times erratically) with the angle of departure, because the drag ratio of the projectile in question to some standard, e.g. to Projectile Type 1, is not a constant. The Ballistic Coefficient in more rigorous applications also includes corrections for variations in projectile stability in order to account for projectile wobble and yaw as it proceeds downrange.

Ballistic Conditions - Conditions which affect the motion of a projectile in the bore and through the atmosphere, including muzzle velocity, weight of projectile, size and shape of projectile, rotation of the earth, density of the air, elasticity of the air and the wind.

Ballistic Curve - Actual path or trajectory of a projectile.

Ballistic Density - Computed constant air density that would have the same total effect on a projectile during its flight as the varying densities actually encountered.

Ballistic Efficiency - Ability of a projectile to overcome the resistance of the air. Ballistic efficiency depends chiefly on the weight, diameter and shape of the projectile.

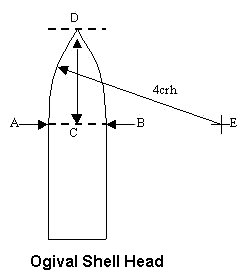

Ballistic Length or Head Length - The length of the projectile's nose. See "crh" below.

Ballistic Limit - Velocity at which a given type of projectile will perforate a given thickness and type of armor plate at a specified obliquity. Also see "Armor Penetration Definitions," in Miscellaneous Definitions.

Ballistics, Internal, Intermediate, External and Terminal - Internal Ballistics is the study of what the projectile does from the moment of firing up until it leaves the muzzle of the weapon. Intermediate Ballistics is the study of the projectile between the time it exits the muzzle until it overtakes the muzzle shock waves and enters normal atmosphere. External Ballistics is the study of what the projectile does as it travels from the end of the intermediate stage to the target. Terminal Ballistics is the study of what the projectile does as it strikes the target.

Balloting - The bounding from side to side of a projectile in the bore of a gun.

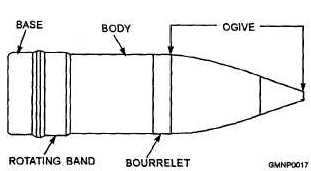

Base - The after end of the projectile, usually described as that portion between the driving bands and the bottom of the projectile.

Base Bleed - This is a unit on the base of a projectile that generates a gas, something like a tracer. What this does is fill in the vacuum that is created behind a rapidly moving projectile and thus greatly reduces the amount of drag acting on the projectile. The gas also acts like a long tail, making the projectile more stable in flight. The end result of these actions is an increase in range and accuracy.

Base Cover - A metal cover that is crimped, caulked or welded to the base of a projectile. This cover prevents the propellant gasses from coming in contact with the explosive filler of the projectile through possible flaws in the metal of the base.

Base Plug - A removable seal in the base of a shell which holds in the explosive filler.

Belt, Ammunition - Multiple rounds of ammunition that are held together by a strip of fabric or metal. Used most often for feeding ammunition to automatic weapons. Ammunition belts may be disintegrating (linked), non-disintegrating or continuous loop.

Blind Shell - A shell containing no explosives or one having its fuzing disabled so that it should not explode. Often used for proof tests against armor plate.

Boat Tailing - Tapering that part of the projectile behind the driving band so as to reduce air resistance (drag), especially at low velocities. This type of design gives a projectile greater range but tends to increase wear on the gun barrel. It was long thought that boat tailing caused greater dispersion in the impact pattern, but a study published in 1978 by the US Army's Ballistic Research Lab showed that the opposite was true.

Body - The cylindrical portion of the projectile between the bourrelet and the driving bands. It is machined to a smaller diameter than the bourrelet to reduce the projectile surface in contact with the lands of the bore. The body contains most of the projectile filler.

Booster - An explosive of special character, usually of high strength and high detonating velocity, generally used in small quantities to improve the performance of another explosive, the latter constituting the major portion of the charge and made up of a less sensitive explosive. Also see "Gaine."

Bourrelet - Finely machined band or ring of metal just behind the ogive of a projectile, designed to support the front portion of the projectile by riding the lands as the projectile travels through the bore of a gun. Only the bourrelet and the driving bands of a projectile actually touch the rifling. Some projectiles have additional bourrelets located near the base of the projectile. On USN large caliber AP projectiles of the World War II period, rear bourrelets were located just before and after the rotating bands. These additional bourrelets act to reduce the tip-off angle by keeping the projectile body centered in the gun barrel after the forward bourrelet has exited the muzzle.

Brisance and Brisant - Brisance is the measure of how rapidly an explosive develops its maximum pressure. A brisant explosive is one in which the maximum pressure is attained so rapidly that the effect is to shatter any material in contact with it and all surrounding material.

Cap or AP Cap or Armor Piercing Cap - Hardened steel

nose piece on an APC projectile. Introduced by Russia and America in 1894 and

adopted by the British Royal Navy in 1903. See illustrations on this

page. The cap serves the following purposes:

1) It is shaped so as to increase

the biting angle; that is, the angle at which the projectile will penetrate

rather than ricocheting.

2) It spreads the shock of impact

over the periphery of the nose instead of allowing the initial contact

to batter the nose tip.

3) It pre-stresses the armor plate

upon impact before the cap shatters away. This means that the shell

body sees a weakened plate.

Cannelure - Means a ring-like groove

or a groove encircling a cylinder. These have the following uses

in ammunition and weapons:

1) On projectiles used in fixed

ammunition: The groove provides a means of securely crimping the

cartridge case to the projectile.

2) On armor-piercing bullets:

The groove is used to lock the jacket of an armor-piercing bullet to the

core.

3) In the rotating band of a projectile:

The groove lessens the resistance from the rifling as the projectile travels

down the gun barrel.

4) Around the base of a cartridge

case: The groove is where the extractor takes hold to eject the spent

case.

5) In the construction of British

large-caliber, wire-wound weapons: Cannelured rings were used to

prevent "steel choke" problems.

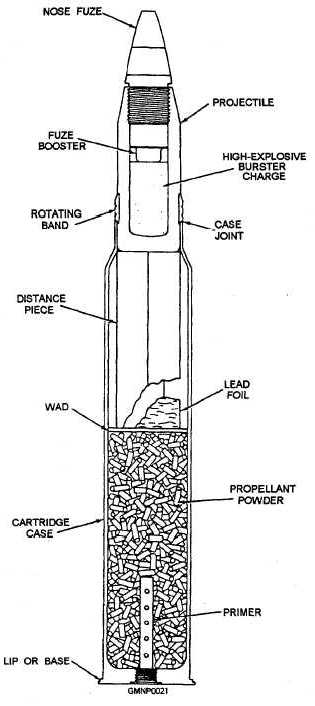

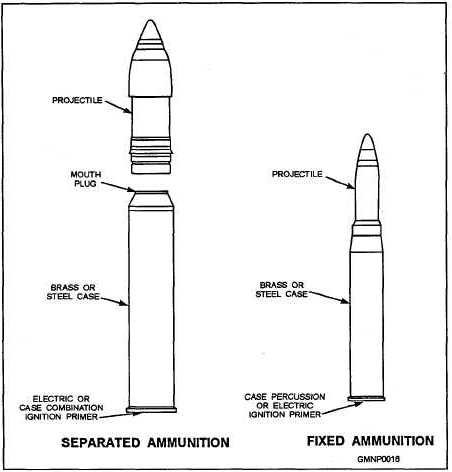

Cartridge - For rifles and pistols, this is usually defined as being the term for a complete round of ammunition, including the projectile, cartridge case, propellant and primer. For larger caliber naval weapons, especially those using separate ammunition, this term is usually applied to only the metallic propellant container, although the British also used this term to describe the individual fabric-wrapped charges used for bag guns. See next definition.

Cartridge Case, Powder Case, Propellant Case or Casing - A metallic container for holding powder charges and usually includes a primer element. This type of propellant container allows higher rates of fire and is less likely to catch fire in case of damage from a shell hit. It is also less likely to suffer a flareback type of disaster caused by the smoldering remnants from the previous powder charge. However, for larger caliber guns, it does require more complicated and heavier handling equipment than does bag ammunition. Germany used a variation of this for their larger guns, where the propellant was divided in to two sections, a fore charge in a bag and a main charge in a cartridge case. Also see "Fixed" and "Semi-Fixed."

Cartridge Case Size - Cartridge cases are usually designated by the diameter of the projectile they fire and by the overall length of the casing. Letter suffixes indicate the type of casing. For example, the famous Oerlikon 20 mm of World War II used 20 x 110RB casings. This meant that the cartridge cases were for 20 mm projectiles, had an overall length of 110 mm and had a Rebated Rim. It should be realized that this is an imprecise method of identifying casings, as it neglects body diameter and shape. Most cartridge cases are of one of the following types:

- Belted - Cartridge cases having a belt of metal above the extraction groove approximately the same diameter as the rim. Denoted by the suffix B after the diameter and length values.

- Rimless - Cartridge cases having an extraction groove with the base of the cartridge case being no wider than the rest of the cartridge case body. This type of cartridge case does not have a suffix following the diameter and length values.

- Rimmed - Cartridge cases having a rim at the base wider than the rest of the cartridge case and not having an extraction groove. Denoted by the suffix R.

- Semi-Rimmed - Cartridge cases that have a rim that is wider than the body of the casing with an extraction groove just above the rim. Denoted by the suffix SR.

- Rebated Rim - Cartridge cases whose bottom rim is smaller in diameter than the body of the cartridge case. There is an extraction groove between the rim and the rest of the cartridge case body. Denoted by the suffix RB.

Cartridge Case, Bottle-Necked - A cartridge case whose main body diameter is significantly larger than that of the projectile and has a short "neck" section which holds the projectile. This design may be used with any of the above cartridge case types. A bottle-neck cartridge case holds more propellant for a given length than will a non-bottle neck cartridge case.

Cartridge Case, Tapered - A cartridge case whose body diameter increases from the neck to the rim. This type of cartridge case ejects easier from the firing chamber than does a "straight" walled cartridge case, as any backwards motion releases the entire cartridge case body from the walls of the firing chamber. Most military ammunition manufactured today has at least some degree of taper.

Case Ammunition - Ammunition using a cartridge case to hold the propellant. See "Fixed" and "Semi-Fixed" below.

Case Plug or Mouth Plug - The sealing device in the mouth of a cartridge case used for separate (semi-fixed) ammunition. This may be of cork, plastic or cardboard. The USN originally used a brass mouth cup to seal cartridge cases, but after one "boomeranged" back on board the transport SS Mongolia and killed two nurses in May 1917, cardboard ones were substituted.

Charge or Powder Charge - The amount of propellant used in firing a weapon. See "Propellants" below.

Clarkson's Case - British propellant charge container. These were flashproof containers for bag charges (cartridges). Charges were placed into these containers before they left the magazines. The Clarkson's Cases then rode up the hoists to the guns where the charges were removed only when it was time to load them into the breech. The Clarkson's Cases were reusable and were returned to the magazines for reloading.

Clearing Charge - A small propellant container that is used to remove a projectile "through the muzzle" following a misfire or when a projectile fails to seat properly and prevents closure of the breech. For semi-fixed (separate) rounds, the propellant case may be easily removed from the breech following a misfire or failure to seat, but there is no easy way to extract the projectile after it has been rammed. A clearing charge casing, being shorter than a standard full-charge casing, is then used to remove the projectile. The clearing charge also gives the projectile a softer blow than does a standard charge and thus provides a margin of safety.

crh - Caliber Radius Head. The pointed head of a projectile is described in terms of its ballistic length and the radius of the curvature of its nose. Larger numbers mean a more streamlined profile. Properly, crh is shown as a dual number such as 3/4crh, with the first number indicating the ballistic length and the second number indicating the radius of the curvature, but it is often abbreviated to a single number such as 4crh. In the sketch at the right, the dotted line between Points A and B is the "shoulder" which is the start point of the nose and the distance between these points is the caliber of the projectile. In this sketch, the radius of the curvature is from Point A to Point E and is four times the caliber of the projectile. The vertical distance between Points C and D is the ballistic length and is the most important factor in the design of a shell for stability in flight. In this sketch, the ballistic length is 4, as Point E is on the same plane as Points A and B. From these numbers, this projectile would properly be described as 4/4crh but this would normally be abbreviated to just 4crh. Shells of this general shape are described as being "ogival headed" and have superior ballistic performance. As can easily be imagined, a 6crh shell is more pointed and streamlined than is a 4crh shell. When crh is described as 5/10crh it means that the radius is 10 calibers long but the ballistic length is that of a 5crh shell. When a projectile is described as 5/∞crh it means that it has a ballistic length of 5 and its nose shape is conical (infinite radius), not ogival. Most USN projectiles had secant ogive ballistic nose shapes which were somewhat more conical than a simple tangent ogive (smooth merging joint with cylindrical lower-body side) and gave them a distinct "shoulder" where the nose met the cylindrical side of the lower body). This shape has slightly reduced air friction compared to a tangent ogive nose of the same length above the cylindrical body. For further information, see the History and Technology Essay Calculating crh.

Dark Tracer and Dark Ignition Tracer - Dark Tracer was non-luminous while Dark Ignition tracers did not ignite until the projectile was 100 to 400 yards (90 to 370 m) from the muzzle. The USN developed these tracers late during World War II for their 20 mm and 40 mm automatic weapons. These tracers eliminated the blinding effect on gunners at night and made the origin of tracer fire harder to determine.

DBX - Depth Bomb Explosive. USN solid explosive developed during World War II to replace Torpex and used mainly for depth charges. It is a mixture of TNT, cyclonite, ammonium nitrate and aluminum.

Density Factor - The weight of a projectile measured in pounds divided by the cube of its caliber measured in inches. For example, the USN 16" (40.64 cm) AP Mark 8 weighed 2,700 lbs. (1,224.7 kg). The density factor of this projectile is thus 2,700 / 163 = 0.659.

Detonator - An explosive device used to set off a larger explosive, such as a blasting cap used to set off TNT.

Distance Piece - This is usually a rectangular cardboard piece folded into a triangular shape and placed into the cartridge case between the wad and the case closure plug or projectile. The distance piece is used to hold the propellant firmly in place when the amount of propellant does not completely fill the cartridge case. Distance pieces are generally used in fixed and semi-fixed ammunition for 40 mm and larger projectiles.

DPICM - Dual Purpose Improved Conventional Munition. A submunition carried as payload in projectiles such as the USN 5" (12.7 cm) Cargo Round. "Dual Purpose" refers to the munition having both anti-personnel and anti-armor capabilities.

Drag - The effect of air resistance on a projectile. Drag (D) = f(V/A) * K * Ø * P * Di2 * V2, where f(V/A) is a coefficient related to the ratio of the velocity of the projectile to the velocity of sound in the medium through which it travels. Sound through air at 68°F (20°C) at sea level travels at 1,128.6 fps (344 mps). K is a constant for the shape of the projectile. Ø is a constant for yaw (deviation from linear flight). P is the density of the medium, Di is the diameter (caliber) of the projectile, and V the velocity. The degree to which a projectile is slowed by drag is called retardation (r) given by the formula: r = D / M, where M is the mass of the projectile. Drag is also influenced by the spin of the projectile. The faster the spin, the less likely a projectile will "yaw" or turn sideways and tumble. However, if the projectile spins too fast, it will not "turn over" at the top of its trajectory (apogee) and so will not strike the target nose-first.

Driving Band or Rotating Band - A raised ring or rings of soft metal encircling a projectile designed for rifled gun barrels. Bands are normally located near the base of the projectile. The bands engage the rifling in the gun barrel, causing the projectile to spin as it travels through the barrel. Additionally, they provide a tight seal so that the propellant gases do not escape past the projectile, help to center the rear end of the projectile in the bore and hold the projectile in place during loading and gun elevation. Bands are typically made of copper, brass or soft steel. USN driving bands on large caliber projectiles were an alloy consisting of 97.5% copper and 2.5% nickel. An "augmented driving band" or "augmented rotating band" is a slightly thicker strip of metal used when the rifling in the gun barrel has been worn down to the point that a standard driving band is no longer effective.

Eccentricity - Distance from the geometric center line of a projectile to the center of gravity of the projectile.

Explosive Train - An explosive train uses the impulse of an initiating explosive to start the chain reaction that leads to the detonation of a main burster charge or ignition of a propellant. For example, a fuze may be initiated by a firing pin striking a small mercury fulminate detonator charge which then sets off a booster charge which in turn sets off the main explosive charge.

Mercury Fulminate - An initiating explosive that may be used as either a primer or a detonator. It may be detonated by flame, friction or percussion and may in turn ignite a booster or it may be mixed with other materials to form a primer composition to ignite a larger charge. Its melting point is too high to allow it to be cast and so it is usually loaded by being pressed into caps. It is affected by high heat and will decompose in storage at tropical temperatures such that at the end of three years it becomes useless. Its color is light yellow.

F or FF - Form Factor. A value used for ballistic calculations. See "Ballistic Coefficient" above.

Fixed Ammunition - Ammunition in which the cartridge case is attached to the projectile, similar to a pistol bullet. This type is usually limited to smaller weapons as the weight becomes prohibitive for hand-worked guns as the caliber increases past about 4 inches (10.2 cm). On my datapages for guns firing this type of ammunition, the value given for "Weight of Complete Round" refers to the total of the individual weights of the projectile, cartridge case, propellant and igniter all added together. The weight of the projectile itself is given separately if available. Also see "Bag" above and "Semi-fixed/Separate" below.

Flechette - A small fin-stabilized projectile. Usually used in large numbers inside of a single carrier projectile.

Full Charge or Service Charge - Propellant loading to drive AP or HE projectiles at full velocity. "Service Charge" was discontinued in the USN during World War II as it caused confusion.

Fuze Setter

1) A machine located on or near the gun

platform that is used to set time fuzes, usually for AA projectiles.

2) A gun crewman whose job it is to either

operate the Fuze Setter machine or, by using a wrench or similar tool,

to manually set projectile time fuzes.

Fuze Setting in the Hoist - Hoist fuze setting was first successfully accomplished by the USN with its 5"/38 (12.7 cm) when coupled with the Mark 37 GFCS. In this system, the projectiles were inserted nose down into a cup on an endless chain hoist that led from the handling room directly below the mount up to the gun breeches. As the projectile traveled up the hoist, a pawl in the cup, driven by the GFCS, would engage a lug on the projectile's time fuze ring. The cup rotated the pawl so as to set the time fuze. The time fuze setting was automatically and continually adjusted during the hoist as the firing solution changed. Loaders were trained to wait until the last possible moment before removing a projectile and placing it on the loading tray so as to get the best possible time adjustment.

Fuze Setting at the Muzzle - Muzzle fuze setting is normally done by induction. The fuze setter itself consists of a ring around the muzzle that generates a weak pulsed-electromagnetic field. As the fuze passes through the ring, it senses this data signal and sets itself accordingly.

Gaine (Booster) - An explosive container detonated by the fuze and which in turn detonates the bursting charge.

Grain

1) A measure of weight used in the UK

and USA for small propellant charges and for the weight of small caliber

bullets. 1 pound = 7,000 grains. 1 gram = 15.432 grains.

2) An individual particle of propellant.

See "Powder Grain" below.

Greenboy - Improved British AP projectile developed late in World War I. The ballistic cap for these projectiles was painted green to distinguish them from older models, hence the nickname. Following the failure of British AP projectiles to detonate properly during the 1915 Battle of Jutland (Skagerrak), the Royal Navy began an intensive effort to produce better versions. These were introduced into service starting in 1918 and had a new delay-action base fuze patterned after the ones used on German 28 cm Psgr. APC projectiles. Greenboys had better armor penetration abilities compared to the older models, thanks to an improved body and the new "Hadfield" hardened AP cap.

Grommet - Cover used to protect the projectile rotating band during handling. The grommet is removed before the projectile is fired.

Head Length - The length of the projectile's nose. Same as "Ballistic Length." See "crh" above.

Hood - Thin cap used on USN Special Common projectiles to attach the windshield to the projectile body.

Hygroscopic - Literally means "water seeking" and is used to describe a material that readily absorbs water (usually from the atmosphere).

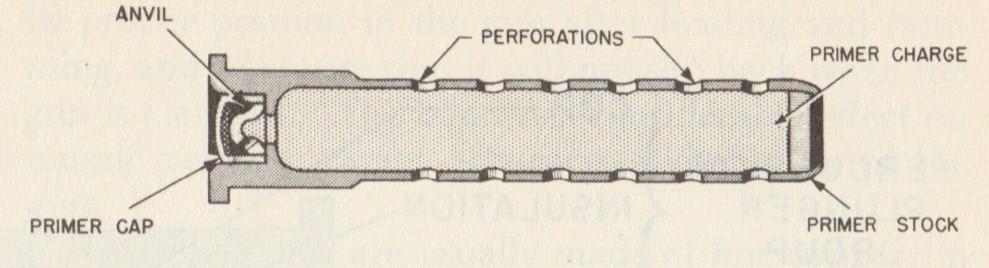

Igniter or Igniter Patch - Bag ammunition charges have a small patch at one or both ends containing black powder (gunpowder). This is used to set off the main propellant charge. See "primer" below.

K Device and A.K. Device - British designations for projectiles using dye bags. K devices had a dye container with a small explosive charge with a fuze that triggered upon water impact. These were used for 6 to 16 inch (15.2 to 40.6 cm) projectiles with the exception of the older 7.5 inch (19 cm) guns which were not issued dye projectiles. A.K. devices were used for 4.5 to 5.25 inch (11.4 to 13.3 cm) projectiles. A.K. Devices did not use an explosive charge. Instead, the ballistic cap had forward and aft ports sealed with brass plugs. Water impact forced out the plugs and water entered through the forward ports, mixed with the dye, and then exited through the aft ports. Red, Yellow and Green dyes were made, with White being available by simply not providing a dye. See "Splash Colors" below.

Lead Foil - A piece of lead foil is sometimes inserted at the top of the propellant in a cartridge case. The lead foil aids in scouring away residue left from the driving bands or unburnt propellant.

Lifting Plug - Threaded eyebolt which fits into the fuze cavity (nose or base), permitting heavy shells to be handled by means of a winch.

Link - The part of an ammunition belt which joins the individual rounds together. Usually, one link holds one round. "Disintegrating Link" means that the links holding each individual round to the next round separate from each other and from the cartridge as each round is fired.

Meplat - The flat or blunt area at the tip of a projectile. Usually specified by its diameter.

MT - Mechanical Time. Designation for Time Fuzes used by the US Navy. See "Time Fuze" below.

Nitrated Cotton - A short-fibered cotton bleached and purified to the point where it is 90% pure cellulose. This material forms the basis for nitrocellulose used in propellants. See "Propellants" below.

Nose Plug - The Lifting Plug (see above) used for nose-fuzed projectiles.

Nutation - The aerodynamic, gyroscopic and inertial forces acting on a spinning projectile are in constant flux as it travels through the air. As the various forces readjust themselves, the nose of the projectile describes a small arc around the axis of travel. This motion is called "nutation" from the Greek word for "nodding," which is a good description of what the projectile actually does.

Obturator - In projectiles, this is a band, usually made of nylon, below the driving bands. The band helps prevent propellant gasses from escaping past the projectile as it travels up the gun barrel. Commonly described as the "Forward Obturator" or "Forward Located Slip Obturator" to distinguish it from the breech obturator.

Ogive - The curved area making up the nose of a projectile. Usually defined as extending rearwards from the tip of the projectile's nose to the main cylindrical portion or bearing surface. From an ordnance manual: "Often a convex solid of revolution generated by an arc of a circle whose center lies on the side of the axis of revolution opposite to the arc." Whew, glad I found that out! In layman's terms, the head of the projectile is usually bullet-shaped. See "crh" above.

Palliser Projectile - Iron armor piercing shells of the mid to late 19th century which were hardened by casting the projectiles point downwards and forming the heads in an iron mold. This process rapidly chilled the hot metal of the nose and made it intensely hard. The remainder of the projectile mold was formed of sand, allowing the metal of the shell body to cool more slowly, making it tough but not brittle. These shells were powder-filled, but did not use a fuze. Instead, they relied upon the shock of striking the target to set off the burster. These shells were effective against wrought iron armor, but shattered against steel armor. Named after the inventor, Sir William Palliser.

Posit or Pozit Fuze - See Fuzes.

Powder Bags - See Bag Ammunition, above.

Pre-fragmented - A projectile, usually AA or antipersonnel, that has been sectioned so as to break up into uniformly-sized pieces when the round detonates.

Puff - Non-explosive projectile used for training spotters. These produce a dense cloud of smoke approximately the size of those produced by high-explosive projectiles.

Rim - The lip or flange around the case head on a cartridge case which provides purchase for the extractor claw.

Ring Fuze - See "Time Fuze" below.

Rotating Band - See "Driving Band" above.

Sabot - Pronounced "sa-BO." Literally means "hoof" in French. This is a lightweight carrier into which a projectile smaller than the barrel diameter (usually called a sub-caliber round) is centered. The carrier fills the bore of the weapon from which the projectile is fired and is normally discarded a short distance from the muzzle. There are two common uses for this type of ammunition. The first use is when the projectile is made from a very heavy, dense material, such as in tungsten penetrators. Making the projectile smaller than the barrel diameter keeps the shell weight about the same as that of a conventional projectile and thus does not overstress the gun barrel. The second use is to give a light-weight projectile a higher muzzle velocity. This means that the same amount of propellant will throw the smaller projectile a longer distance than it will the conventional projectile.

Sankaidan - Japanese for "fragmentation." Also known as "incendiary shrapnel shells" (shôi ryûsandan). These were AA rounds which contained hundreds of incendiary-filled steel tubes and officially designated as "Type 3 Common Shells" (3 Shiki tsûjôdan). The incendiary filling was "Elektron" metal (45%), barium nitrate (40%) and rubber (14.3%) together with sulfur (0.5%) and stearic acid (0.2%). "Elektron" was a trade name for a metal alloy composed primarily of magnesium (90%) with the balance being aluminum (3%), copper (3%), zinc (2%) and silicon (2%). Besides their incendiary effect, the steel tubes also acted as shrapnel. The Type 3 was first deployed in 1942 for 20 cm (8 in) and larger guns and in 1943 for the 12.7 cm/40 (5 in) AA and 12.7 cm/50 (5 in) DP guns. The 46 cm (18.1 in) Type 3 projectiles for the Yamato class battleships may have been nicknamed "The Beehive" but this could be apocryphal. A time fuze was used to set the desired bursting distance, usually about 1,000 meters (1,100 yards) after leaving the muzzle. These projectiles were designed to burst in a 20 degree cone extending towards the oncoming aircraft with the projectile shell itself being destroyed by a bursting charge to increase the quantity of steel splinters. The incendiary tubes ignited about half a second later and burned for five seconds at 3,000 degrees C, producing a flame about 5 meters (16 feet) long. These shells were thought to have a larger lethal radius than did standard HE AA rounds. The concept behind these shells was that the ship would put up a barrage pattern through which an attacking aircraft would have to fly. However, the USN pilots considered them to be little more than fireworks and not an effective AA weapon.

SD - Sectional Density. A value used for ballistic calculations. See "Ballistic Coefficient" above.

Semi-fixed and/or Separate Ammunition - Semi-fixed ammunition is when the projectile and cartridge case are separate pieces but are joined together prior to firing. This term has become interchangeable with separate ammunition, which is where the projectile does not attach to the cartridge case but they are both rammed together into the breech. These types of ammunition were commonly used for AAA and DP type weapons used in World War II as this allowed each piece to be light enough to be manually handled. For example, the US 5"/38 (12.7 cm) Mark 12 used a projectile with a separate brass cartridge case which held the propellant. These were laid together in the gun's loading tray after which the rammer pushed them "home" into the breech which then closed automatically. Technically, the 5"/38 (12.7 cm) used separate ammunition, but most descriptions of this weapon, including USN official ones, use the term semi-fixed. In more recent years, the USN has adopted the term "Separate Ammunition" as the preferred description for this type of ammunition.

Set-back - The shock on a projectile when fired from a gun or when it strikes a target. Used to enable many fuze mechanisms such as impact and time fuzes.

Shalloon - See "Bag Ammunition" above.

Shark - A British ASW projectile developed near the end of World War II. Weighed about 96 lbs. (43.5 kg) and could be fired from any 4 inch (10.2 cm) gun. Not known if successful in battle, but trial results were considered to be very encouraging.

Shell Length - This is sometimes designated as being in "calibers," similar to barrel length. For instance, if a 16 inch (40.64 cm) shell is listed as being 4 calibers long, then this means that it is about 16 x 4 = 64 inches (1.626 m) long from nose to base.

Short Delay Fuze - See "Contact Fuze" below.

Shot - An archaic term for a solid projectile intended for penetrating armor. Mostly replaced by AP after about 1900.

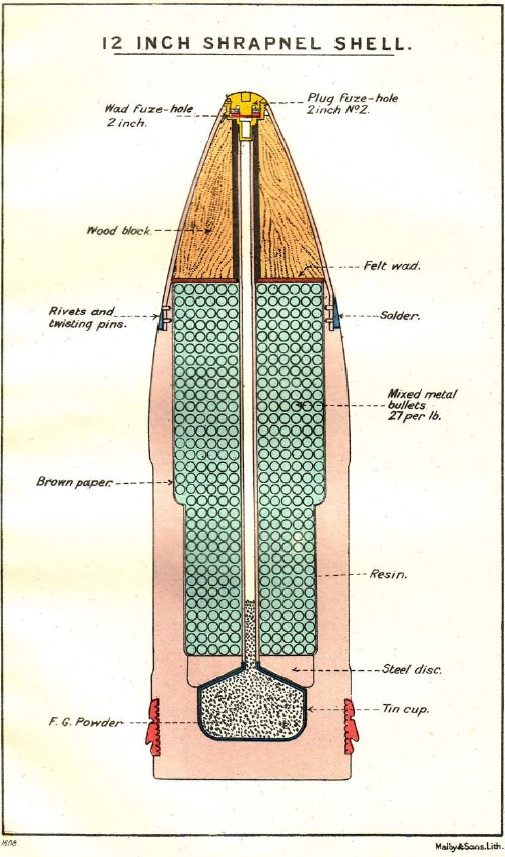

Shrapnel - Also known as "spherical case," this was a type of anti-personnel ammunition which consisted of a shell containing metal balls in the front and a small bursting charge at the base which was detonated by a time fuze set to explode just before reaching the target. This was first adopted by the British Army in 1803 and is named after the inventor, Lt. (later General) Henry Scrapnel (sometimes spelled as "Shrapnel") of the British Army. This term has been used in the past to define shell fragments from most kinds of bursting projectiles, not necessarily anti-personnel types. Currently, the more accurate term "shell splinter" is in general use.

Spin - A standard, fin-less projectile must be spun in order to maintain stability in flight. Under or over spun projectiles will tend to tumble in flight or not turn over at apogee and thus do not achieve good range or penetration performance. Generally speaking, the larger the diameter or longer the projectile, the slower it can be spun, in terms of rotations per second (RPS), in order to maintain stability.

Special Charge - Any charge other than Full, Reduced, Target or (USN term only) High Capacity

Splash Colors - In group actions, when more than one ship is firing on the same target, it is difficult to determine which shell splashes are from which ship. This is important to know in order for each ship to be able to accurately adjust its fire onto the target. The solution was "Splash Colors," first used by the USN during Force Battle Practice in 1930 and in use by most navies during World War II. The void space between the armor piercing cap and the windshield for AP projectiles was filled with a colored dye by the shell manufacturer. The dye is seen when the shell impacts in the sea and colors the resulting splash - hence the name. By using different colors, each ship could distinguish between their shells and those fired by other warships. In the USN, the dye was a dry powder which was packaged in paper bags. Interestingly, the USN used this dye to compensate for minor weight variations that crept in during the projectile manufacturing process. For example, the 16 inch (40.64 cm) Mark 8 AP had a nominal 1.5 lbs. (0.68 kg) dye bag, but this was allowed to be as large as 3.0 lbs. (1.36 kg) in order to bring underweight projectiles up to the standard weight of 2,700 lbs. (1,225 kg). Usually, a particular color was assigned to each ship. For example, the colors used by the USS Iowa (BB-61) class battleships were as follows:

USS Iowa - Orange

USS New Jersey - Blue

USS Missouri - Red

USS Wisconsin - Green

Splinter or shell splinter - Fragments of a shell after detonation.

Star Shell - See "Illum" above.

Super Quick Fuze - See Fuzes.

Time Fuze - See Fuzes.

TP-T - Target/Practice projectile with Tracer.

TTB - Target Triggered Burst. See Fuzes.

VD - Variable Delay. USN terminology for base fuzes designed for armor-piercing projectiles. Complete designation was "VDXF" where "X" was the Mark number and "F" stood for fuze. See Fuzes.

VT - Variable Time. See Fuzes.

Wad - For cartridge cases using a loose powder propellant which does not fill the cartridge, a cardboard disc is placed on top of the powder and held with a distance piece to keep the propellant firmly in place.

Windshield - See "Ballistic Cap" above.

World War I Projectile Weight - Typical World War I AP caps weighed about 5% of the total projectile weight. World War I windscreens, when used, were tiny, only about 0.5-2% of the projectile weight. The need for increased range caused more World War II-like long windscreens to be added to some projectiles by the end of World War I. Burster weight was about 2.5-4% for APC, 4-6% for Common, 6-11% for HE and about 8-10% for CPC.

World War II Projectile Weight - Windscreens weighed 3-5% (depending on length) for most World War II projectiles, though German post-1930 L/4,4 and L/4,6 AP projectiles used brittle aluminum windscreens that only weighed about 1% of the total projectile weight. Hoods weighed about 5%. AP caps had more variable weights, with 8-14% being the usual range for large projectiles. Smaller projectiles, especially U.S. Navy 6 inch (15.2 cm) and 8 in (20.3 cm) AP projectiles, had much heavier caps. The U.S. Navy 335 lbs. (152 kg) 8 inch (20.3 cm) Mark 21 AP projectile had about a 17% cap weight, while the 130 lbs. (59 kg) 6 inch (15.2 cm) Mark 35 AP projectile had a 19-22% cap weight - both of these projectiles had the bluntest, most-hemispherical nose shapes of all projectiles in use. Explosives made up about 2-5% for APC, although the USN used about 1.5% in their "super-heavy" projectiles. HE or HC projectiles had about 6-8% explosive. Some exact breakdowns:

USN 16 inch (40.64 cm)

2,700 lbs. (1,225 kg) AP Mark 8 Mod 6 (Data from NPG Report 3-47)

AP

cap: 312 lbs. (141.5 kg) [11.6%]

Windscreen:

32.4 lbs. (14.7 kg) [1.2%]

Bursting

charge: 40.5 lbs. (18.4 kg) [1.5%]

Body

weight (including bursting charge): 2,355.6 lbs. (1,068.5 kg) [87.2%]

German 40.64 cm (16

inch) 2,271 lbs. (1,030 kg) Psgr. L/4,4 (mhb) (Data from NPG Report 101)

AP cap: 363 lbs. (164.7 kg) [16%]

Windscreen: 27 lbs. (12.3 kg) [1.2%]

Bursting charge: About 53.4 lbs. (24.2 kg) [2.3%]

Body weight (including bursting charge): 1,880 lbs. (852.8 kg) [82.8%]

The explosive charge within a shell is known as the "Bursting Charge" or, more simply, as the "Burster." Some of the more well-known:

- Black Powder or Gunpowder - Used as the burster in most shells prior to the early years of the twentieth century. A common procedure was to fill the shell cavity with gunpowder or to put the explosive into a loosely-restrained bag at the base of the projectile. In this latter variation, when the projectile struck the target it was intended that the bag would be torn loose from its restraints and flung forward against the interior of the shell. In either variation, these projectiles relied upon impact shock to set off the burster. About as reliable as it sounds, hence the intensive search for better explosives, more reliable fuzing and the interest in the Zalinsky "Dynamite Gun" experiments.

- Composition RDX/BWX-91/9 - British burster for 40 mm ammunition made from 91% RDX and 9% beeswax as a desensitizer. This was investigated by the USN but beeswax was in short supply and it was feared that it would melt under tropical conditions. See Composition A-3 below.

- Composition A-3 (ca. 1945) - USN burster made from a mixture of 91% RDX and 9% plasticizing oil, aka microcrystalline wax. The wax acts as both a desensitizer and as a lubricant which allows it to be pressed into a shell body. Introduced in the USN in 1945 for use in AA projectiles. Tests with 5" (12.7 cm) VT-fuzed shells found that the lethal radius of Composition A-3 was larger than the effective radius of the VT fuze.

- Composition A-3 (modern day) - USN burster made from a mixture of 91% RDX and 9% polyethylene wax now used in current 5" (12.7 cm) HE ammunition.

- Composition A-5 - Explosive consists of a pressable mixture of 99% RDX coated with 1% Stearic Acid. It comes in the form of white or colorless granules without visible impurities or signs of moisture.

- Composition Exploding or CE - See "Tetryl" below.

- Gun Cotton - See "Propellants" below.

- Explosive D - USN burster made from "Dunnite" which is Ammonium Picrate, a salt formed from picric acid. Named after its inventor, Major (later Colonel) Beverly W. Dunn (1860-1936) US Army. Adopted by the US Navy in 1911, this explosive is very insensitive to shock, giving it a high margin of safety. Initially, the USN used a mixture of Explosive D in the forward part of the projectile with black powder in the back of the projectile. In 1917, the burster for projectiles between 5 and 8 inches (12.7 and 20.3 cm) was changed to a mix of TNT and black powder while larger projectiles were filled completely with Explosive D. Problems with deflagration on impact with these large-caliber projectiles led to a change to a higher density packing in 1923 and this was so successful that most projectiles were then made with Explosive D bursters until well after World War II. Explosive D is insensitive enough that it does not need "shock absorbing" materials or the addition of desensitizing materials to the burster in order to prevent impact prematures such as were required for other burster explosives in use during World War II. Picric acid-based explosives, including Explosive D, are corrosive to many metals and can form dangerously sensitive compounds which can cause a bore premature. For this reason, the interior walls of the projectiles were coated with varnish as a preventative measure. For the same reason, cardboard disks and tubes were used to prevent direct contact between the fuzes and the Explosive D bursters. However, Explosive D gives off fumes which were corrosive to the aluminum and zinc parts in the fuzes. This corrosion essentially prevented the small fuze parts from moving freely during the arming process, causing a number of duds in combat. In addition, moisture, especially in high humidity climates like the South Pacific, would penetrate into the fuzes and also cause corrosion problems. The problems were recognized and corrected during World War II. Special gaskets were placed in the joints of the fuzes and a silica gel bag was placed into one of the fuze cavities to absorb any moisture that made it past the gaskets. Finally, to make them airtight, the fuzes were coated with a bakelite varnish over a lacquer base.

- HMn - Hydrazine Mononitrate. Most commonly used as a rocket fuel, but also used by the French Navy as a burster in a few projectiles.

- PBX - Plastic Bonded Explosive. A mixture of cyclonite, HMX, PETN and a plastic binder. Has high mechanical strength, excellent chemical stability and is shock resistant.

- PETN - Pentaerythritol tetranitrate. Shock-sensitive material used in explosives, blasting caps and in some mono-propellants.

- Pentolite - A mixture of TNT and PETN, usually 50/50. This was not as stable as TNT in storage. Used in some USN 20 mm ammunition during World War II.

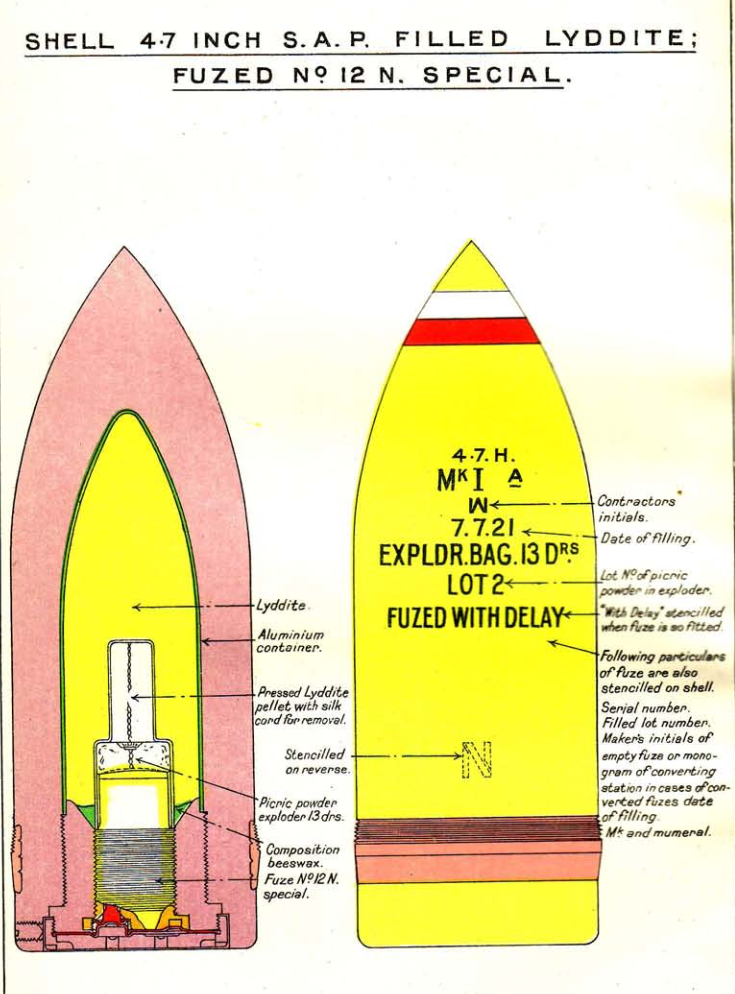

- Picric Acid - A trinitrated derivative of phenol or trinitrophenol. Invented by the German chemist Hermann Sprengel and patented in 1885 by the French chemist Eugène Turpin in pressed and cast form for use in blasting charges and artillery shells. Picric acid was originally made from nitrated indigo and was used as a dye before it was known to be a high explosive. Later formulations used nitrated coal tar products, known chemically as "trinitrophenol." Picric acid is a powerful explosive but its strong acidity is corrosive to many metals and can form dangerous compounds. To prevent this, most nations applied a layer of varnish to the burster wall before filling. British shells using Lyddite and Shellite bursters had an aluminum container which was expanded into the burster cavity to hold the burster. This reduced the chances of spontaneous explosion upon impact and also isolated the burster should the projectile body crack after filling.

- Ecrasite - Austria-Hungary picric acid.

- Emmensite - US Army picric acid. It does not appear that this form of picric acid was used for USN bursters. A 1910 US Naval Academy text book mentions it, but says that it was experimental at that time. The 1915 edition of this text book does not mention Emmensite at all. As noted above, Explosive D was adopted by the USN in 1911, so Emmensite may never have been used for USN bursters. The USN did experiment with their own form of picric acid for their "High Explosive" bursters in the early 1900s before adopting Explosive D. This was made from 87% picric acid along with 10% dinitro-benzol and 3% vaseline used as desensitizers. This burster explosive was apparently only known in the USN as "picric acid," it does not appear to have had a unique name.

- Eversite - Italian picric acid.

- Lyddite - British picric acid diluted with dinitro-benzol and vaseline, also known as trinitrophenol. Prior to 1908, the British used gunpowder as the burster for both AP and Common shells, but after that date Lyddite came into use for Common projectiles. In 1909, the Royal Navy began experimenting with APC using Lyddite as the burster and began introducing them into service the following year, even though testing had shown that this filling was more sensitive to shock than gunpowder and thus prone to explode prematurely before the shell had a chance to penetrate almost any thickness of armor plate.

- Mélinite - French picric acid.

- Picrine - German picric acid. Also known as Füllpulver 88 where 88 = 1888.

- Shimose - Japanese picric acid. Named after its inventor, Shimose Masachika (also spelled as Shimose Masakazu), but there is some evidence that it was actually based upon a sample of Mélinite brought back from France. Adopted on 17 February 1893. Also known as PA bakuyaku (picric acid explosive).

- RDX and RDX/BWX - Research Department Explosive. Also known as cyclonite, hexogen and Rapid Detonation Explosive. Invented by a German chemist in 1898, this explosive was widely used by Britain, Germany and the USA during World War II as it was a more powerful explosive than TNT. Sometimes mixed with beeswax (BWX) to reduce sensitivity.

- Shellite - British burster adopted to replace Lyddite. The well-known failure of British APC to penetrate German armor at Jutland (Skagerrak) was partly due to the sensitive nature of the Lyddite bursters which caused many shells to explode immediately following impact on the target. In the next few years, a new burster called "Shellite" was developed which was a mixture of Lyddite and dinitrophenol (DNP), which was a much weaker and insensitive explosive. Originally, a mixture of 50/50 was used, but this gave insufficient fragmentation. Tests with 60% Lyddite and 40% DNP bursters were satisfactory, and it was this combination that was used for the first "Greenboy" APC projectiles issued beginning in 1918. Soon after the end of the war, it was determined that a 70/30 mixture would give improved fragmentation while maintaining an adequate margin against premature explosions. This mixture was used for all subsequent bursters using this explosive.

- Mélinite fondue dinitronaphtaline or Mn.F.Dn - French burster consisting of 80% picric acid and 20% dinitronaphtaline, roughly equivalent to British Shellite. Used in at least the 330 mm OPf(K) RC Mle 1935, 380 mm OPf(K) RC Mle 1936 and 203 mm OPf(K) RC Mle 1936 projectiles in the 1930s-40s.

- Tetryl - Trinitrophenylmethylnitramine. A sensitive, high power burster. Tetryl is a light yellow crystalline material and was first made in 1877. Known in the British Royal Navy as Composition Exploding or CE.

- TNA - Tri-nitro-aniso. German and Japanese naval military explosive, originally developed by Germany for mines and torpedoes, but also adopted by Japan to replace Shimose. The Japanese designated TNA as Type 91 bakuyaku (Model 1931 Explosive) and this was adopted on 25 July 1931. TNA is a methylated derivative of picric acid and is a more stable burster than Shimose. However, it is still quite sensitive to impact shock and 33-40% of the burster cavity was used as a jacket surrounding the actual filler, with a thick plaster case all around the TNA and a thick wood and aluminum cushion filling the upper end of the cavity.

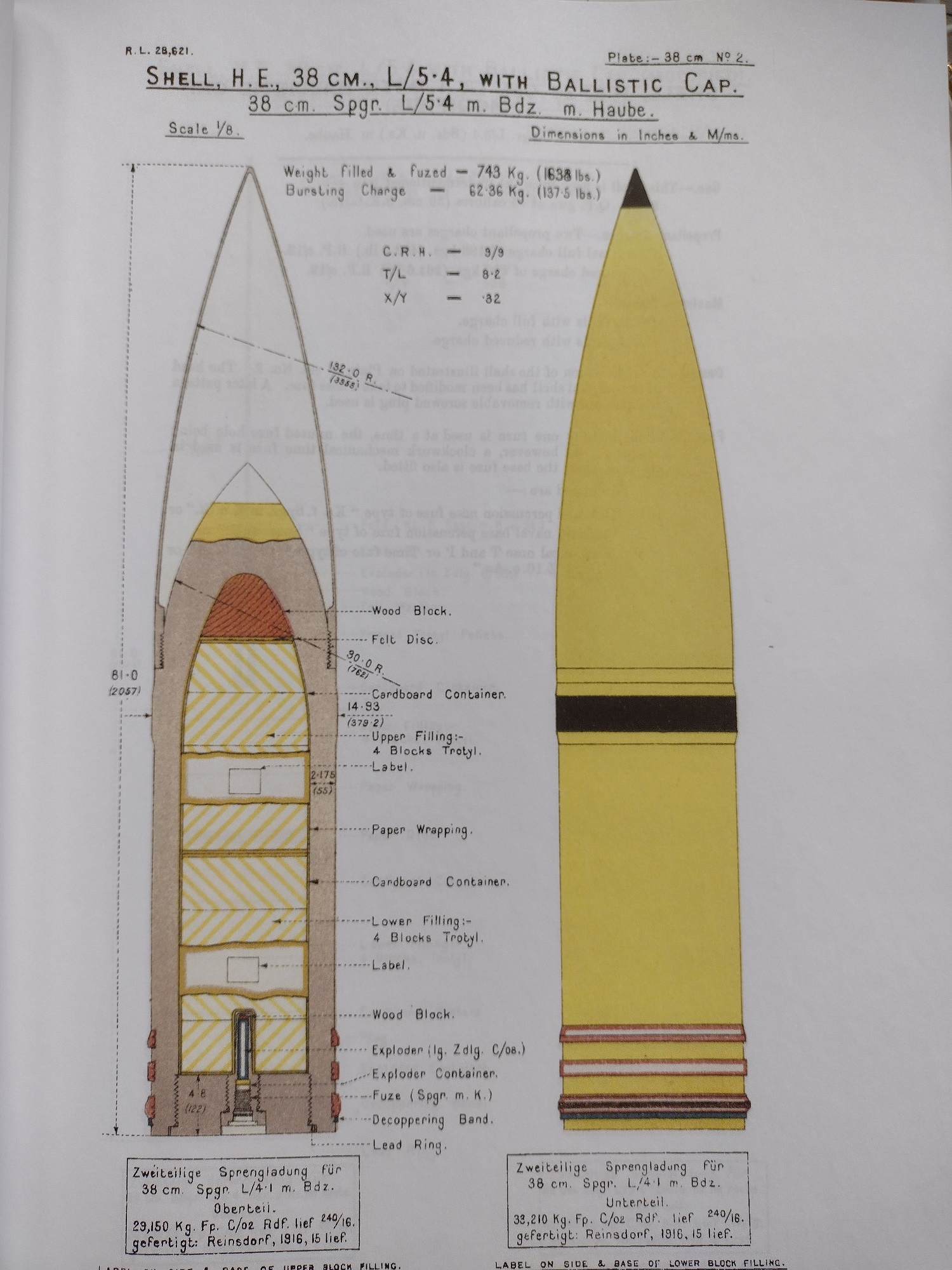

- TNT - Tri-nitro-toulene. Few nations used pure TNT in their bursters. Instead, TNT was usually mixed with a desensitizer, such as beeswax. For example, many German shells used a TNT/beeswax mixture made into blocks which were pre-formed to the cavity shape. A large wooden cushion at the top of the cavity was used in some shells to lessen the impact shock and thus reduce the chances of a premature detonation. Italian burster designs were similar, but used a wooden "cushion" in the rear of the burster cavity as well as in the nose of the cavity. British TNT bursters had about a 3-5% beeswax content and used a small (~5% of burster cavity) shock absorber cushion made from plaster-of-Paris or pitch in the nose of the cavity.

- Trotyl - British name for TNT.

- Before and during World War I

- Black powder = 0.33 to 0.50

- Guncotton = 0.50

- Picric Acid = about 1.05 to 1.10

- USA Explosive D = 0.95

- After World War I

- British Shellite = 0.96

- French Mn.F.Dn (Mélinite/Dinitronaphthalene 80/20) = 0.88

- British and Italian TNT = about 0.97 (beeswax content at 3%)

- German TNT = 1.00 (German reiner Sprengstoff burster weights did not include the beeswax desensitizer weight)

- Japanese TNA = 1.05

- USA Explosive D = 0.95

- World War II

- UK RDX/BWX and USA Composition A-3 = about 1.7

- Other Explosives (torpedo warheads, mines, depth charges)

- Amatol (80/20) = 1.24

- DD (Dinitronaphthalene/Dinitrophenol 60/40) = 0.82

- PETN = 2.21

- RDX = 1.94

- Tetryl = 1.39

- Torpex (TPX) = 1.50

- HBX-1 = 1.17

- HBX-3 = 1.14

- German SW types = about 1.07

- Japanese Type 97 (TNT/hexanitrodiphenylamine 60/40) = about 1.07

Sensitivity - A measure of the degree to which an explosive can be initiated by impact, heat, or friction. Two scales are used to denote the sensitivity of USN explosives. The first is the "Laboratory Impact Sensitivity" (LIS) which is a percentage ratio of the drop height necessary to detonate a given weight of explosive as compared to the drop height necessary for TNT. The LIS of TNT is thus set at 100%. The second scale is "Bullet Impact Sensitivity" with RDX rated at 0% and TNT rated at 100%. Other explosives are expressed in relation to these two explosives. This test measures the bullet impact force necessary to set off a given weight of an explosive as compared to the impact force necessary to detonate the same weight of TNT and RDX.

Two rules of thumb about Burster Power

1) The effect of the burster may be taken as being proportional to the

square root of the weight of the bursting charge.

2) For the same basic shell design, the size of the bursting charge is

proportional to the cube of the bore size.

For more information on military explosives, see the Nathan Okun essay Military Explosives (RTF File).

A fuze is a device that initiates the detonation of the projectile burster. Fuzes may be divided into two general categories, contact and non-contact. Examples of contact fuzes would be super quick and delay while examples of non-contact fuzes would be time and proximity. An overview of fuzes and fuze terminology used since the 1900s follows below.

ADF or Auxiliary Detonating Fuze - Many USN nose fuzes have an "auxiliary detonating fuze" between them and the burster. These auxiliary fuzes provide the heavier shock which actually detonates the bursting charge. Auxiliary fuzes also act as a safety feature by preventing the projectiles from exploding should the primary fuze be accidentally actuated prior to the arming of the auxiliary detonating fuze.

Boresafe Fuze - Type of fuze having an interrupter in the explosive train that prevents the fuze from functioning until after the projectile has cleared the muzzle of the weapon. A "non-boresafe fuze" does not have this feature.

Base Fuze - Fuze located at the bottom end or base of the shell. This is the most common location for AP and SAP projectiles as it avoids weakening the nose of the shell and protects the fuze from damage as the projectile passes through armor. Some HE/HC shells have both nose and base fuzes as this increases the probability of the shell detonating under differing conditions.

CCF - Course Correcting Fuze. A smart fuze that uses aerodynamic fins together with the Global Positioning System (GPS) in order to steer an otherwise ordinary ballistic projectile.

Contact, Impact or Percussion Fuze - A fuze initiated only after the projectile strikes the target. There are two general types of contact fuzes: "Delay" and "Super Quick" both further defined below.

Combination Fuze - A fuze that incorporates both Contact and Time functions. The fuze may function either when it strikes the target or after the set time expires.

Delay Fuze - A contact fuze that detonates the projectile only after it has impacted and penetrated some distance into the target. A "short delay" means that the fuze initiates detonation within a few thousandths (0.00X) of a second after impact. For naval guns, short delays are generally used for HE/HC rounds while longer delays are used for AP rounds. Some delay fuzes have a ring or dial which allows adjustment of the delay time. For AP projectiles, it is desirable to have the shell detonate only after it has penetrated past the armor plating, thus letting it get into the "vitals" of the target ship's interior. For most AP rounds of the twentieth century, this delay was usually about 0.030 to 0.070 seconds, roughly equivalent to 35 to 80 feet (10 to 25 m) of travel. In addition, some thickness of armor plate was needed to initiate the fuze action. For example, the USN required that for hits of 0 degrees obliquity that the AP fuze would not activate unless the armor plate was at least 1 inch (2.54 cm) thick.

Nose Fuze - Fuze is located at the top point of the shell. This is the most common location for HC and HE shells as the fuzes can be set to allow little or no time delay and thus detonate the bursting charge immediately upon impact.

Proximity Fuze - Fuze containing a simple radar that can detect the nearness (proximity) of a target. Also called "influence fuze." First used in World War II on USN 5 in (12.7 cm) AA shells which were called "VT Fuzed" where VT stood for "Variable Time" (it appears to be a myth that "VT" was a reference to "Section T," the BuOrd development team for proximity fuzes. See the History and Technology Essay on VT Fuze naming). These fuzes are also widely used for anti-personnel rounds for land artillery as they eliminate the need to accurately set a time fuze to explode the projectile at a fixed distance above the target. During World War II, the US Army called these posit or pozit fuzes which meant that the proximity fuze allowed the shell to detonate at the most effective height or "position" above the ground. Since World War II, proximity fuzes small enough to fit onto 40 mm AA rounds have been developed. The modern British versions of proximity fuzes are called TTB - Target Triggered Burst. CVT or "Controlled Variable Time" fuzes have a mechanical timer which activates the radar when it is close to the target. This helps to prevent premature detonations due to heavy rain or other non-target influences.

Super Quick Fuze or Instantaneous Fuze - A contact fuze designed to detonate the projectile before it has penetrated any distance into the target. Super quick fuzes are commonly used on anti-aircraft rounds that are intended to shred the outer airframe.

Time Fuze - Fuze has an adjustable mechanism - usually an incremented dial or "ring" that controls a mechanical or electronic timer which is used to set a delay time. Commonly used for AA, smoke and illumination projectiles, this type of fuze is used to control the time between when the shell is fired and when it detonates.

AA - Anti-Aircraft.

AAC - Anti-Aircraft Common.

AAVT - Anti-Aircraft with Proximity Fuze.

AHEAD - Advanced Hit Efficiency And Destruction.

AP - Armor Piercing. Projectile for use against heavily armored targets. Very little explosive within the shell, as it must be almost solid in order to penetrate through armor plate. The USN has designated all capped armor piercing projectiles as AP since the early 1900s. See "APC" below.

APC or CAP - Armor Piercing Capped or (rarely used) Capped Armor Piercing. Most AP shells have a hard steel cap fitted over the nose which is intended to exert a high initial force on the face of the armor. In addition, a ballistic cap is usually fitted over the AP Cap to provide a more streamlined shape for better aerodynamic characteristics.

APCBC - Armor Piercing Capped with Ballistic Cap. This is a good description but somewhat of a made-up designation, as it was not actually used by any nation.

APDS - Armor Piercing Discarding Sabot.

APFSDS - Armor Piercing Fin-Stabilized Discarding Sabot.

API, AP-I, APT or AP-T - Armor Piercing Projectiles that include a Tracer (Incendiary).

AR - British designation meaning "Anti-Radar." See "Window" below.

BL&P or B.L.&P. - Blind Loaded & Plugged. Same as a Blind Shell. Used for training purposes or for target practice.

BL&T or B.L.&T. - Blind Loaded Shell with a Tracer. Used for training purposes or for target practice.

BTERM - Ballistic Trajectory Extended Range Munition. See 5"/62 Mark 45 Mod 4 for details.

CCAMS - Course-Corrected Anti-Missile Shell.

CI - Cast Iron. Dummy Practice projectile.

Common - Common projectiles were originally shells - which literally means a hollow container - filled with black powder and used for attacking lightly armored or unarmored vessels. By the 1930s, this term was used by a few navies to describe any non-armor piercing shell. By that time, the bursters were less sensitive explosives, such as TNT. In the USN, Common projectiles of the 1920-1950 period did not have caps or hoods and were designed to penetrate approximately one-third of their caliber of armor. See "Special Common" below.

CLGP - Cannon-Launched, Guided Projectile. Long-range ballistic projectiles using terminal laser guidance developed during the 1970s for the USN's 5"/54 Mark 42 and 8"/55 Mark 71 guns.

CNF - Common, nose fuze. British projectile designation.

CP - Common Pointed. British designation for shells of poured or cast unhardened steel. Used a powder filling and were manufactured for 2-pdr. to 6 inch (15.2 cm) guns. These were sometimes called SAP (see below) projectiles. Obsolete by World War II.

CPBC - Common Pointed Ballistic Cap. British designation for shells with ballistic caps of 6 inch (15.2 cm) and larger intended for use against medium thicknesses of armor. After 1946 this designation was changed to SAPBC - Semi-Armor Piercing Ballistic Cap.

CPC - Common Pointed Capped. British designation for capped shells of 6 inch (15.2 cm) and larger for use against lightly armored targets. Used a mild steel cap. Little armor penetration capability but large bursting charge. Obsolete by World War II.

DART - Driven Ammunition Reduced Time of flight. Sub-caliber guided projectile with canard control, intended to improve the performance of the OTO-Melara 76/62 gun in the antimissile role. Uses a radio-frequency beam rider guidance system which utilizes the firing ship's tracking radar.

ERGM - Extended Range Guided Munition. See 5"/62 Mark 45 Mod 4 for details.

FAP - Frangible Armor Piercing. FAP is usually a projectile with a tungsten alloy core which breaks up into multiple fragments when it strikes a hard surface. The FAP projectile combines armor penetration, blast effects and incendiary action, all from an inert projectile that has no more logistical safety problems than a training round.

FAPDS - Fragmented Armor Piercing Discarding Sabot.

FATO - Fonte Aciérée, Tronqué, Ogivé - French Cast iron steel shells with a truncated ogive.

HC - High Capacity. A USN designation for projectiles intended for use against lightly armored targets. Contains a relatively large amount of explosive as compared to an armor piercing or common projectile. Burster was between 7.0% to 12.6% of total projectile weight. BuOrd experimented with various Army and Navy fuzes and developed three variations for at least the 6" (15.2 cm) and 8" (20.3 cm) HC projectiles. The directive allowed gun crews to replace the nose fuze with Point Detonating (PD), proximity (VT), time (MT) or a plug and the base fuze with a plug. This allowed the crews to customize projectiles best suited to be used against either shore objectives, lightly armored surface craft or aircraft as needed.

HCHE - High Capacity High Explosive. A version of HE-T that uses a special grade of steel to allow it to penetrate steel plates up to 20 mm thick before fuze initiation.

HE - High Explosive or High Effect. Similar to HC.

HEI or HE-I - HE projectiles that include an Incendiary.

HE-I-SD - Self-destructing incendiary HE projectile.

HE-CVT - HE with a Controlled Variable Time (proximity) fuze. Fuzes have a timer which delays activating the radar until it is close to the target. This helps to prevent premature detonations due to heavy rain or other non-target influences.

HE-IR - HE with an infrared fuze. These rounds use a passive IR fuze that operates only on the infrared spectrum detected in the exhaust gasses of jet and hot missile targets. These fuzes are harder to jam than radar-type proximity fuzes.

HE-MOM - HE Multirole OTO Munitions. OTO-Melara ammunition with proximity fuzing and tungsten cubes surrounding the bursting charge.

HE-PF-OM - HE Pre-Fragmented OTO Munition.

HE-PD - HE with a Point Detonating (contact) fuze.

HE/SD - Self-destructing HE projectile.

HENT - British HE shell with TNT burster.

HET or HE-T - HE shell with a tracer.

HE-T/SD - Self-destructing HE-T shell.

HETF - British high explosive projectile with time fuze.

HE-VT - High Explosive with a Variable Time (proximity) fuze.

HVP - Hyper Velocity Projectile. See 5"/62 Mark 45 Mod 4 for details.

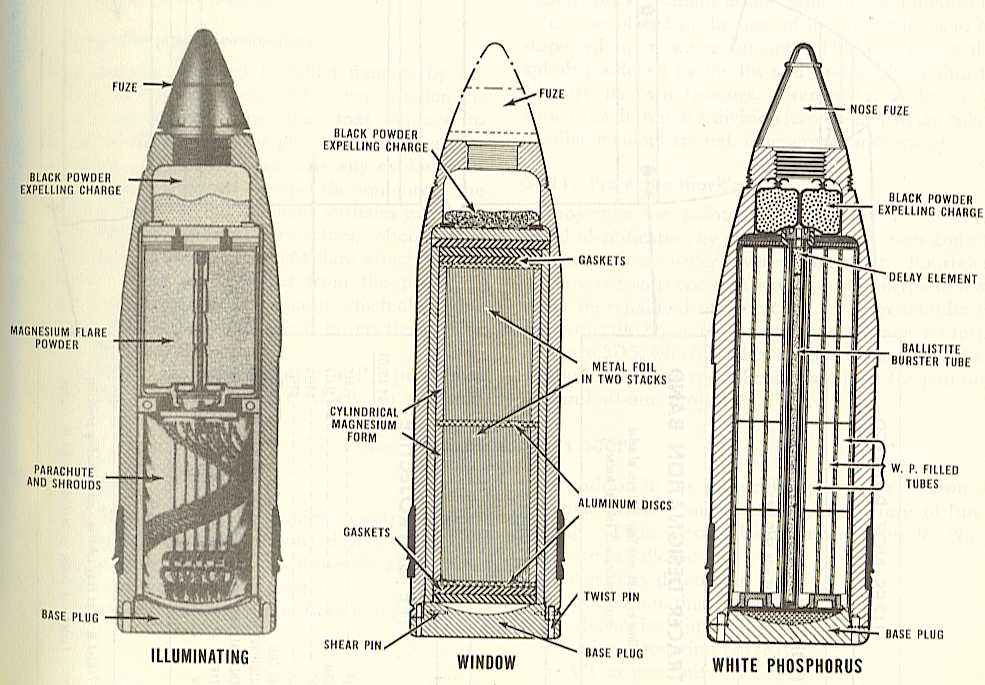

ILLUM or Illuminating - Commonly called "Star Shells," these projectiles are usually filled with magnesium and are used at night to light up (illuminate) the target. Many use a parachute in order to slow their descent.

ILLUM-MT - Illumination round with a Mechanical Time fuze.

LRBA - Long Range Bombardment Ammunition. USN munition developed as part of the "Gunfighter" program of the late 1960s. These were unguided 5" (12.7 cm) projectiles enclosed in a sabot and fired from 8" (20.3 cm) gun barrels. These sub-caliber projectiles had a maximum range of about 72,000 yards (66,000 m) and were successfully used against Viet Cong targets at 70,000 yards (64,000 m).

LRLAP - Long Range Land Attack Projectiles. These are being developed as part of the AGS program.

MPDS - Missile Piercing Discarding Sabot.

MPT - Multi-purpose Tracer. An explosive round that does not use a fuze but instead uses an incendiary charge inside the nose which sets off the main burster.

OEA - Obus Explosif en Acier. French designation for High Explosive projectiles projectiles made with steel bodies.

OEcl - Obus Eclairant. French designation for Starshell.

OI - Obus Incendiare. French designation for Incendiary shell.

OPf - Obus de Perforation. French designation for Armor Piercing shell - SAP - but was also commonly used for APC and SAPC.

OPFA - Obus de Perforation en Fonte Aciérée. French designation for Semi-Armor Piercing shell made with Cast Iron Steel bodies.

OPf RC - Obus de Perforation de Rupture Coiffé. French designation for Armor Piercing shell with an AP cap - used for both APC and SAPC.

OPfK or OPf(K) - Obus de Perforation dispositif 'K'. French designation for Armor Piercing shell with dye bag. Unlike many nations, French dye shells included a nose fuze and a small explosive charge to disperse the dye. This made it possible to not only color the shell splashes but also to color hits.

PFHE - Proximity Fuzed High Explosive.

RAP - Rocket-Assisted Projectile.

RE - Radar Echo - British designation for Chaff shells, later replaced by AR - See above.

SAP - Semi-Armor Piercing. Projectiles supplied for smaller guns for use against moderately armored targets. Projectiles generally have a thicker nose and a smaller burster compared to HE projectiles.

SAPC - Semi-Armor Piercing with a thin Armor Piercing Cap. May have a small Ballistic Cap.

SAPBC - Semi-Armor Piercing with a Ballistic Cap.

SAPCBC - Semi-Armor Piercing with both a Ballistic Cap and an Armor Piercing Cap.

SAPER - Semi-Armor Piercing Extended Range.

SAPHEI-T - Semi-Armor Piercing High Explosive Incendiary Tracer.

SAPOM - Semi-Armor Piercing OTO Munition.

SAPOM-ER - Semi-Armor Piercing OTO Munition Extended Range.

Special Common or SP Common - USN unofficial designation of the 1920-1950 period for those Common projectiles that used both windshields and hoods. These projectiles were designed be able to penetrate approximately one-third to one-half their caliber of armor. They differed from AP projectiles by not having a cap and in having a larger burster cavity. Burster was 2.1% to 3.99% of total shell weight.

Shrapnel Shell or SS - British designation. A thin-walled shell body with a powder filled central tube surrounded by lead antimony balls embedded in resin. Used a time fuze. Obsolete by World War II.

Window or Window Load - Projectiles containing metal foil strips, which, when scattered high in the air by a small burster charge, serve to jam radar sets by creating a multitude of images. Also known as "Chaff" shells.

WP - White Phosphorous or "Wiley Pete." Projectiles used to create a small smoke screens, which is why they are also known as "Smoke" rounds.

An overview of propellants and associated terms used by naval guns since the 1860s.

- Black Powder - Commonly known as "gunpowder," this was obsolete as a propellant by the 1880s and rarely used after 1900 by the major powers. It did continue to be used for igniter patches on bag ammunition. Black powder is a mixture of potassium nitrate or sodium nitrate, charcoal and sulfur. It is hydroscopic and subject to rapid deterioration when exposed to moisture. It is also one of the most dangerous explosives to handle because of the ease with which it is ignited by heat, friction or spark. Black powder as a gun propellant has several disadvantages: (1) it leaves a large amount of residue, (2) it produces large quantities of smoke, (3) it causes rapid erosion of the gun bore and (4) its velocity of reaction is too rapid, giving an abrupt hammer blow to the projectile and then rapidly decreasing energy. This last reason is why gunpowder guns had short barrel lengths. Muzzle velocity was generally less than 1,600 fps (488 mps).

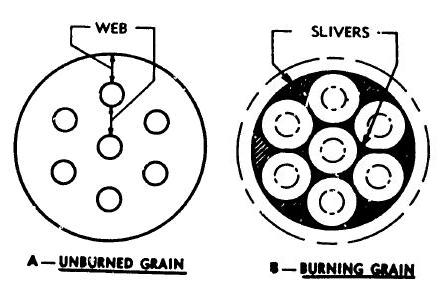

- Prismatic Powder - In 1860 General Thomas Jackson Rodman of the United States Army, realizing the advantages to be gained by increasing the propellant burn time, proposed the use of large grains of very dense black powder for this purpose. As a result of his research, he also proposed that perforated grains be used in order that the burning surface of each grain might be increased as combustion proceeded. The use of these grains gave a means of better regulating the ballistic action of black powders, and thus reduced undesirable items such as fluctuations in muzzle velocity. Different grain forms were tried, such as spherohexagonal and various prismatic shapes, including the hexagonal prism with a single perforation. The latter form was widely used in larger guns. The use of such grains was the first notable advance in securing a powder which would burn progressively, that is, with increasing evolution of gases and heat.

- Brown Powder or Cocoa Powder or Slow Burning Cocoa - Invented in Germany in the late 19th century, this was gunpowder that was made by using an underburned straw charcoal that gave it the characteristic color from which it took its name. This charcoal gave a denser and hence slower burning structure to the powder and thus permitted better regulation of pressure. Brown powder is similar to black powder (gunpowder), each being a mixture of potassium nitrate, charcoal and sulfur, but brown powder has a lower sulfur content (3% versus 12%) and a correspondingly higher potassium nitrate content. The reduced sulfur content results in a slower rate of deflagration (burning) and the higher potassium nitrate content supports a more complete burning of the charcoal and thus releases more energy. The slower burning nature of brown powder allowed longer barrel lengths and thus higher muzzle velocities, with the maximum being about 2,200 fps (671 mps). However, this propellant is notorious for producing vast quantities of smoke as only about 35 percent of its weight is actually converted into propellant gas.

- Gun Cotton or Nitrocellulose - Explosive substance formed by the nitration of cotton or some other form of cellulose. As a projectile force, gun cotton has around six times the gas generation of an equal volume of black powder and produces less smoke and less barrel heating. Guncotton releases about 1,100 kilocalories (Kcal) of energy per kilogram, nearly twice that of black powder, almost the same as TNT and two-thirds that of nitroglycerin. Moist or "wet" guncotton is relatively stable but can be easily exploded by using a small amount of dry guncotton (which is sensitive to shock) to start the deflagration. Some history about guncotton: In 1838 the French chemist Theophile Jule Pelouze discovered that an explosive could be produced by nitrating cotton, that is, by treating cotton with nitric acid in such a way as to cause NO2 groups from the nitric acid, HNO3, to enter into combination with the cotton cellulose. He thus produced cellulose nitrates, generally called nitrocellulose. His explosive was the first guncotton, but it was an inconsistent mixture and was not put to practical use. The German-Swiss chemist Christian Friedrich Schönbein discovered in 1845-46 that by nitrating cotton with a mixture of nitric and sulfuric acids, an explosive of good quality would result and that the nitration process could be satisfactorily controlled. Manufacture of guncotton via his process was undertaken in several European countries, but poor quality control led to a series of disastrous explosions in many of the factories where it was being produced. The researches of various investigators during the middle of 19th century, notably those of General von Lenk in Austria and the British chemist Frederick Abel at Woolwich Arsenal (who, together with James Dewar, later invented cordite), showed that the danger was due to the presence of impurities, which could be removed by careful courses of treatment. The methods of purification which they introduced consisted principally in washing and boiling, together with pulping the material to facilitate cleansing. In 1865, Abel was the first to safely produce good quality guncotton. Guncotton of this kind was primarily used as an explosive. The use of guncotton as a single-base propellant was invented by the French chemist Paul Vielle in 1883 and involved the "gelatinization" of nitrocellulose. Gelantinization consists in transforming fibrous nitrocellulose into a dense, non-porous material that looks like celluloid and can be given a definite shape. As invented by Vielle, this process involved dissolving nitrocellulose by the use of a solvent mixture, such as alcohol and ether. As the solvent evaporates, what is left behind is a gel - hence the name "gelantinization" to describe the process. This gel produces an energetic material that can be worked into different forms. This is sometimes called a "Solvent Propellant" to distinguish it from "Solventless Propellants."

- Solventless Propellants - These are double-base propellants that use a plasticizer, usually nitroglycerin, which is worked into the nitrocellulose fibers under the mechanical effect of a roll mill and the use of heat to produce a gel. Following this mixing process, the gel is then pushed through an extrusion press to form the propellant grains. These operations are known as "rolling and drawing."

Single-Base, Double-Base, Triple-base and Composite Base Propellants - Propellants are normally classified into three types; single-base, double-base and composite. Single base propellants are primarily gelatinized nitrocellulose that do not contain an additional explosive ingredient such as nitroglycerin. Double-base propellants are mainly compositions that are predominately nitrocellulose and nitroglycerin. Triple-base propellants are double-base propellants to which has been added a third explosive, Nitroguanidine (see below). Composite propellants are compositions that contain mixtures of fuel and inorganic oxidants but do not contain a significant amount of nitrocellulose or nitroglycerin. There are also combinations of composite and double-base propellants.

Charge Assessment - The process of determining the propellant weight necessary to achieve nominal new gun velocity for specific lot of propellant. When a new lot of propellant is produced a series of test firings is conducted to determine the correct charge assessment. This process is called "powder proof." Current practice is to fire a series of tests in three or four different gun barrels. Charge weight is varied and pressure and velocity is recorded for each shot. The results of these tests are then used to calculate the proper charge weight.

Propellant Weights - In almost any reference or official document, propellant weight is given as a fixed number. In reality, as each batch or lot of propellant will be slightly different in its energetic power from any other lot, the weight of an individual charge will depend upon just how "powerful" was the lot of propellant from which it was made. In order to ensure consistency in muzzle velocity from shot to shot, a "Charge Assessment" is made for each lot to determine the proper weight for individual charges. This means that the actual weight of a charge from a particular batch of propellant may be different than a charge made from a different batch of propellant. This is especially the case for large-caliber guns which use a very heavy charge. So, when you see a charge weight given for any particular weapon, understand that this is really the nominal weight of the propellant charges and may not be the the actual weight of all charges for that weapon.

Cordite - A double-base smokeless powder composed of nitroglycerin, guncotton and a petroleum substance, usually gelatinized by the addition of acetone, and the mixture then pressed into cords which resemble brown twine.

Nitroguanidine (NQ) - Needle-shaped solid used in explosives and triple-base smokeless propellants. Nitroguanidine is an insensitive, non-flammable explosive used to reduce flash in propellants. NQ lowers the temperature of the flame and increases gas volume. This combination reduces flash and has a side effect of reducing gas temperatures which reduces bore erosion and thus increases barrel life.

Smokeless Propellant - Propellant formulation that reduces the amount of smoke emitted from the gun muzzle. Examples of Smokeless Propellants would be single-base nitrocellulose like United States SPD and double-based nitrocellulose-nitroglycerin like British cordite. These are not really "smokeless" but are much less so than black powder (gunpowder) or brown powder. In photographs or videos of guns using these propellants, the heavy black smoke seen comes primarily from the black powder igniters used to start the deflagration of the smokeless propellants.

Flashless Powder - Propellant formulation that reduces the amount of flame emitted from the gun muzzle. Useful in night engagements not only because it does not give away the position of the firing ship, but, more importantly, it does not blind the gunners and optical fire control operators. Not really "flashless" but much less so than standard propellants. Flashless propellants normally produce significantly more smoke than do smokless propellants, and there is always the need to strike a balance between the two effects.

Oxidizer - Reactive compound which gains electrons during an oxidation-reduction chemical reaction. In propellants, this is the ingredient that provides oxygen for the burning process.